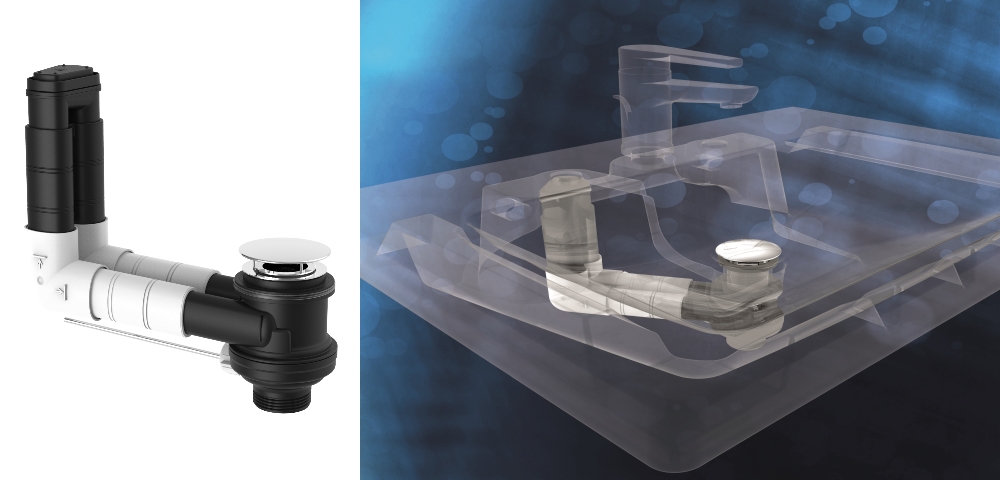

The latest product highlight from the long-established company SANIT is called INEO FLUX. This unique product concept can be used universally for washbasins that do not allow for a visible overflow due to their uninterrupted shape and design. The modern component design of the waste and overflow kit also allows extremely flexible adjustment of the overflow level. The resulting water level can be safely and individually adapted to suit each user's needs.

The components are produced by conventional injection moulding using one of the latest manufacturing technologies available. Simultaneous material processing results in product components that do not require any disruptive or loose sealing parts. The materials used are of the highest quality, giving the waste concept an overall impression of lightness and reliability. Because the components interlock, it is possible to make infinite adjustments without cutting to size, even once the product is already installed. At the same time, the installation work required is reduced to a minimum, and is made noticeably easier by the additional installation key. The infinite telescopic adjustments in the horizontal and vertical direction mean that it is also ultra-flexible, allowing it to be adapted to a wide range of different washbasin shapes and materials.

In addition, INEO FLUX is easy to clean and efficient, thanks to the flow-optimised design of its cross sections.

Total reliability hidden from view: thanks to its integrated return flow protection and the use of a valve unit for ventilation, INEO FLUX offers continuous performance throughout its entire period of use. The cover is opened and closed by a lever system. A sealable valve plug with a float is used in the stem valve. A plastic chrome-plated valve plate is available as an accessory. INEO FLUX meets EN 274 requirements.